Copyright © Wuxi Mingcheng Transmission Technology Co., Ltd. All Rights Reserved.

Google Analytics Technical Support:NSW

Edge banding conveyor belt is widely used in all walks of life. With the wide application of mechanical automation, conveyor belt can replace a large number of labor and efficiency.

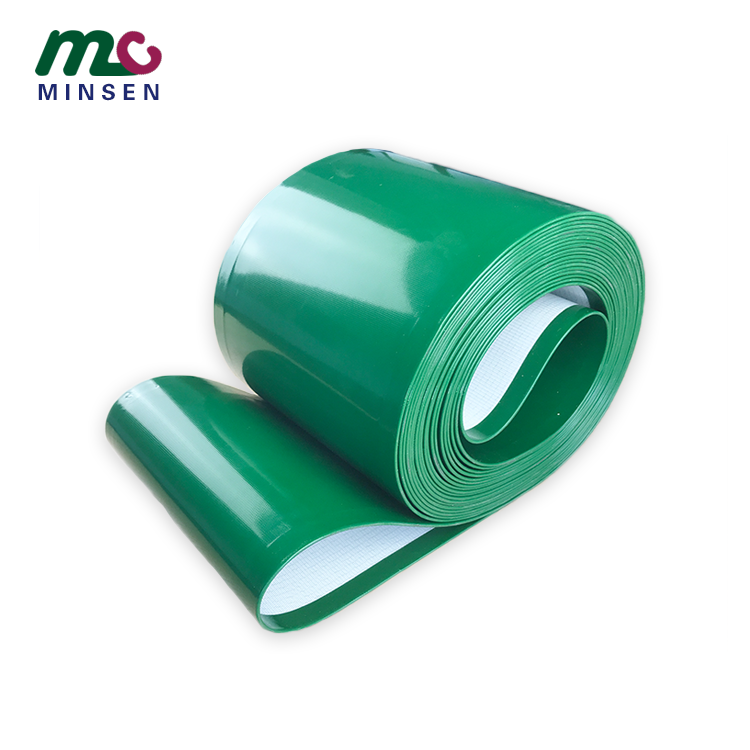

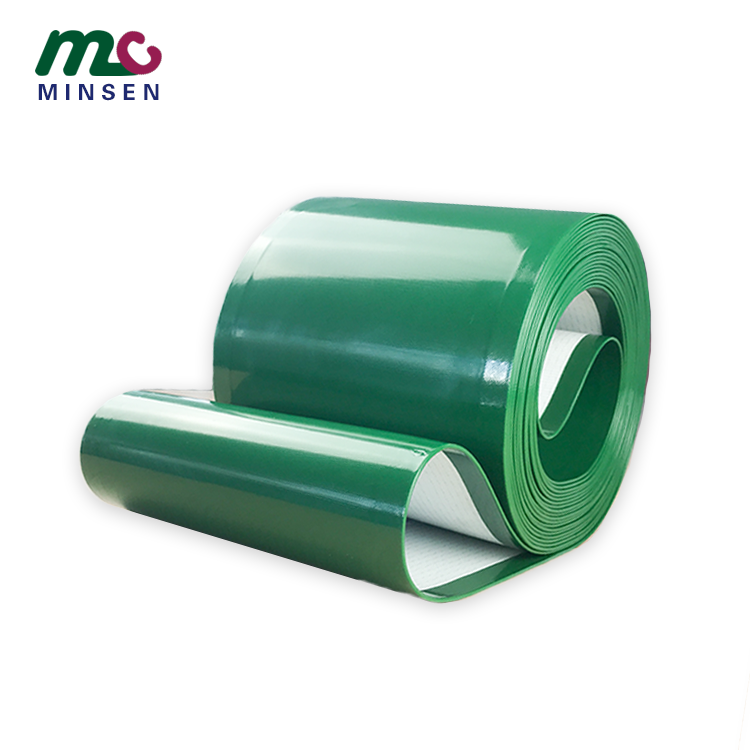

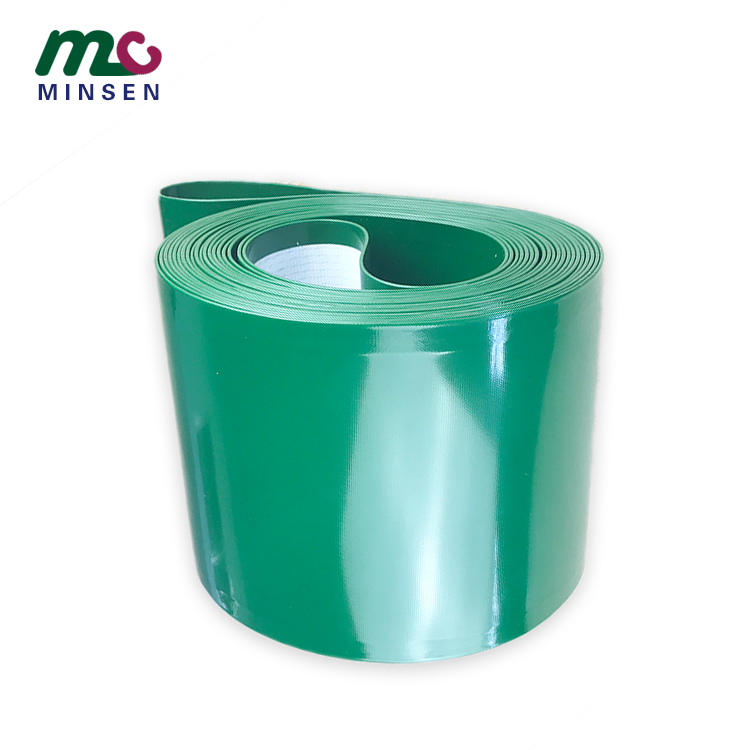

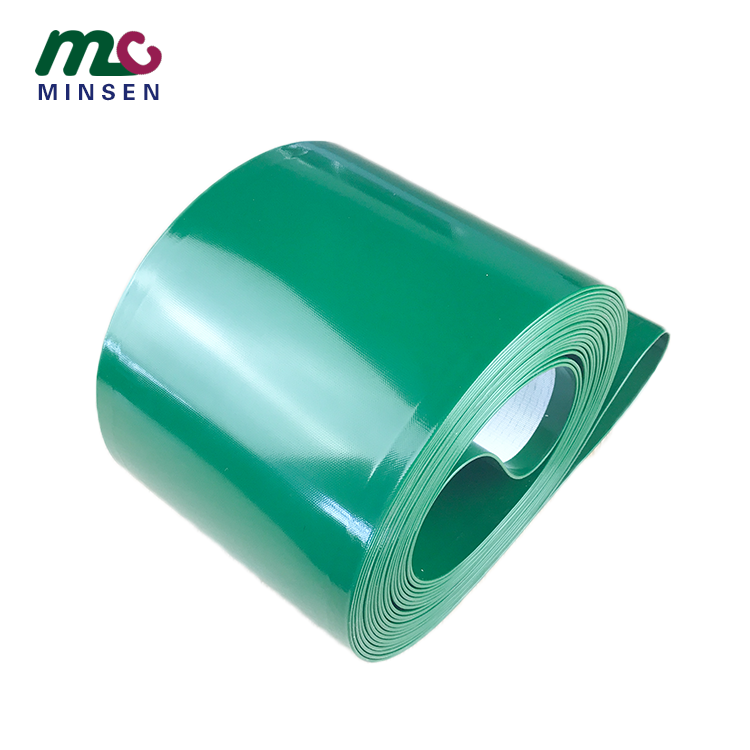

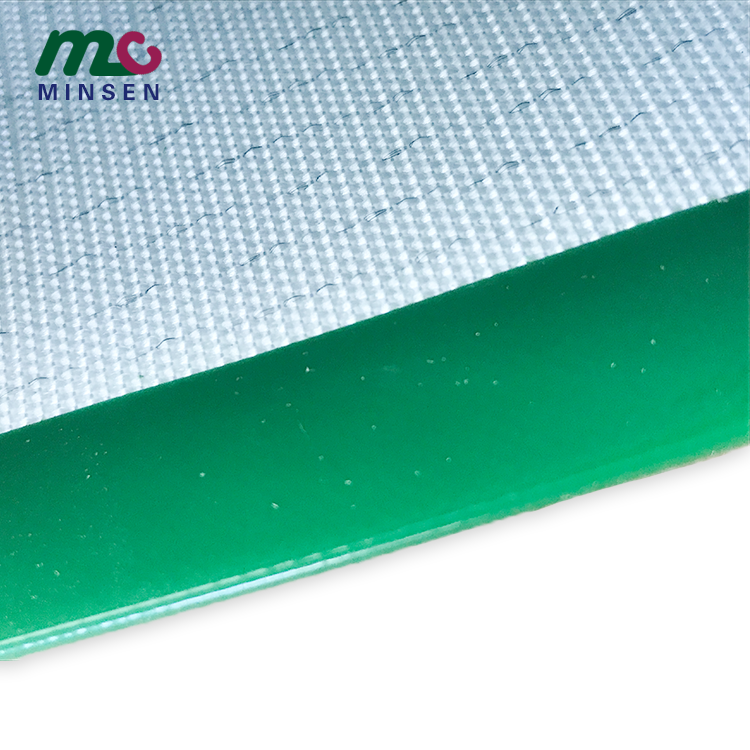

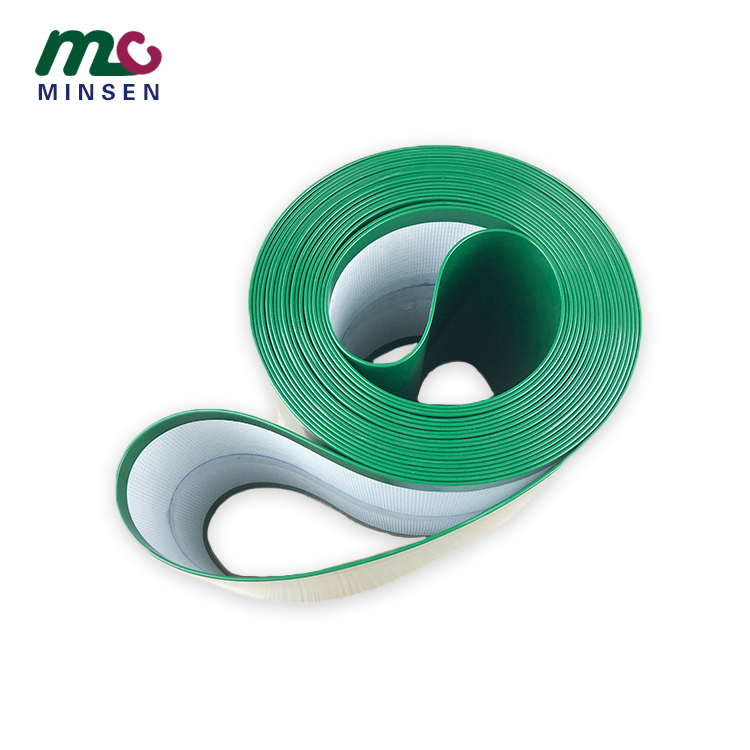

Furniture edge banding machine belt is a kind of product in the machineryindustry, furniture edge banding can be seen in our life. The belt of furniture edge banding machine is a kind of PVC material. Generally, the thickness of 1.0mm and 1.5mm are more used.

Edge banding conveyor adopts manual or full-automatic edge banding machine for edge banding, or manual edge banding. No matter which, the procedure of edge banding is: gluing the edge of the plate or edge banding belt - pressing the edge banding belt on the plate - excess edge banding flush - excess edge banding trimming on both sides - trimming. For full-automatic edge banding machine, there are functions such as edge milling, tracking trimming, scraping, polishing, etc. The key point of edge banding is that the edge of the plate should be straight, there should be no steps caused by the dislocation of large and small saw blades, and it should be pressed tightly, otherwise it is easy to produce gaps between the edge banding and the edge of the plate. When the edge banding is done manually, the special glue for edge banding should be used. It is not recommended to use energy glue, which is easy to fall off in case of heat.

The edge banding conveyor belt can be divided into two types: the conveyor belt with skirt without partition and the conveyor belt with skirt with partition. The lifting baffle belt can make all kinds of bulk materials to be continuously transported at any angle of 0-90 degrees, with large conveying angle, wide range of use and small floor area.

The lifting baffle belt has no transportation point, can reduce the civil construction investment, and has the characteristics of low maintenance cost and large transportation volume, which solves the transportation angle

that the ordinary conveyor belt or pattern conveyor belt cannot reach.

The lifting baffle belt can be designed as a complete conveying system according to the requirements, avoiding the hoisting system of discontinuous conveying and complex conveying.

The lifting baffle belt can transport all kinds of bulk materials, such as coal, ore, sand, fertilizer and grain, along the horizontal, inclined, vertical and variable angle directions.

The lifting baffle belt can make the material particle size unlimited, from very small particle size to 400mm large particle size, and the conveying capacity can be from 1m3 / h to 6000m3 / h.