Copyright © Wuxi Mingcheng Transmission Technology Co., Ltd. All Rights Reserved.

Google Analytics Technical Support:NSW

In almost every field of the printing industry, machine belts can convey, fold or package printed or unprinted paper.

The new belt is adopted to make full use of the quality and productivity potential of the equipment under test. The highly modular thermoplastic strength layer is made of polyester fabrics combined with high wear-resistant surface, which can be widely used in the packaging field from paper feeder to the most diverse equipment.

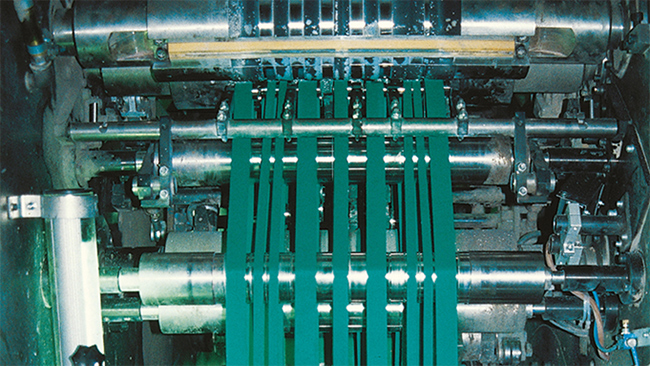

1.Offset/Thermosetting Ink Printing on Commercial Roll Paper (Folding Machine)

The paper speed of 18 m/s can be achieved by using folding tape with special strong layer only. The most diverse types of paper must be transported through folders accurately and reliably, and the belt must have a long service life.

Conveyor belt uses a strong layer of polyester-based fabrics to meet these requirements without reducing edge stability or transverse tear resistance.

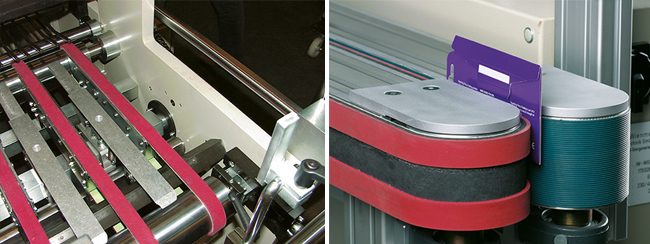

2.Sheet-fed offset press (paper feeding, folding)

The exact feeding of paper into printer plays a decisive role in the continuous production of offset printing.

In addition to elastomer-coated belts commonly used in paper feeders, more alternative products with fabrics, polyurethane or soft polyamide surfaces are available.Conveyor belt has the best load/elongation and is not affected by environmental conditions, so no re-tension is required after long operation.

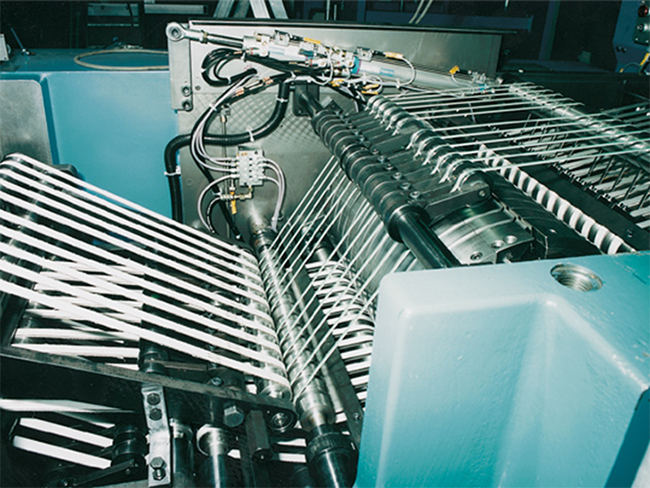

3.Gravure printing of web paper: folder and paster

For paper that has just been printed, folding requires belt conveyor to be accurate and flexible, with no marking on any aspect of the folding machine - especially in the cutting section.

The advantage of the combination of conveyor belt strength layer and polyester non-woven coating is that it can meet the requirements of double width folder and reduce blurring as much as possible.

4.Newspaper Printing/Room Temperature Printing (Folding Machine)

The abrasive properties of printed newspapers require the belt in folding machine to have a high wear-resistant surface.

Adhesion or impregnation of the surface can prevent ink staining and increase the service life.

5Post press processing

Paste box belt

All our products have the highest performance and durability, which helps to maintain quality and efficiency in the following applications.

MINSEN is a conveyor belt manufacturer. The company is located in Wuxi, located on the beautiful shore of Taihu Lake, east of Shanghai-Nanjing Expressway, north of Beijing-Shanghai High-speed Railway, only 10 minutes from Wuxi Airport.

The substrate belt belongs to the plane high-speed transmissionbelt. Usually, the substrate belt has a base layer of nylon in the middle, andthe surface is covered with rubber, cowhide and fiber cloth. It is divided intorubber nylon sheet base band and cowhide nylon sheet base band.

Product Name:timing belt Material:Pu, rubber Color:white, black Specification:customized Processing and customization:Yes. Application:mechanical manufacturing.

Product Name:timing belt Material:Pu, rubber Color:white, black Specification:customized Processing and customization:Yes. Application:mechanical manufacturing.